Applications

Our machines are widely applied across textile finishing and nonwoven, covering a broad range of industrial techniques. Through precise control of temperature, tension, and speed, we help customers achieve stable fabric quality, improved production efficiency, and greater process versatility. Whether for functional fabrics, specialty materials, or high-end apparel textiles, we offer tailored and efficient solutions to meet diverse manufacturing demands.

Heat-Setting

Heat-setting is the core process in textile finishing. With precise temperature and tension control technology, our machines ensure stable fabric dimensions and consistent width while enhancing hand feel and wrinkle resistance. From functional fabrics to premium apparel textiles and specialty materials, we deliver the most reliable and efficient solutions.

Drying

Our drying technology offers highly efficient thermal utilization and uniform airflow distribution, enabling rapid and thorough drying with significantly lower energy consumption. Precise process control preserves fiber structure and hand feel while ensuring consistency in subsequent processing stages — achieving the perfect efficiency and quality.

Pre-Shrinking

Pre-shrinking is a crucial step in garmenting. Our pre-shrinking solutions accurately control shrinkage and enhance hand feel, significantly reducing dimensional change after washing. The process not only improves garment quality but also enhances softness, bulkiness, and drape — providing high-value, ready-to-use textiles.

Coating

Our coating solutions support a wide range of application methods, enabling uniform and precise deposition of functional materials on fabrics or substrates. With fine control of coating thickness and adhesion, we help customers achieve superior performance. From ultra-thin nano layers and foam coatings to complex flocking process, we deliver high-efficiency, high-quality coating results.

Laminating

Our laminating equipment integrates multiple bonding technologies to securely combine fabrics, films, or substrates in two-layer or multi-layer structures. Whether using eco-friendly PUR hotmelt adhesives for breathable yet high-strength composites, or ultrasonic welding for seamless and efficient localized bonding, we ensure excellent peel strength, durability, and lightweight functional performance.

Washing

Washing is a key process for fabric cleanliness and quality improvement. Our de-oiling and scouring machines deliver high-efficiency washing performance, thoroughly removing oils and impurities while achieving excellent shrinkage control. The unique design significantly reduces water and energy consumption, helping customers achieve green and efficient production without compromising quality.

Slitting

Our slitting machines provide high-precision cutting solutions for a wide range of nonwoven materials, including elastic and 100% cotton. With an advanced tension control system, we provide clean edges, zero fraying, and highly accurate strip dimensions slitting solutions — maximizing product quality and yield rate.

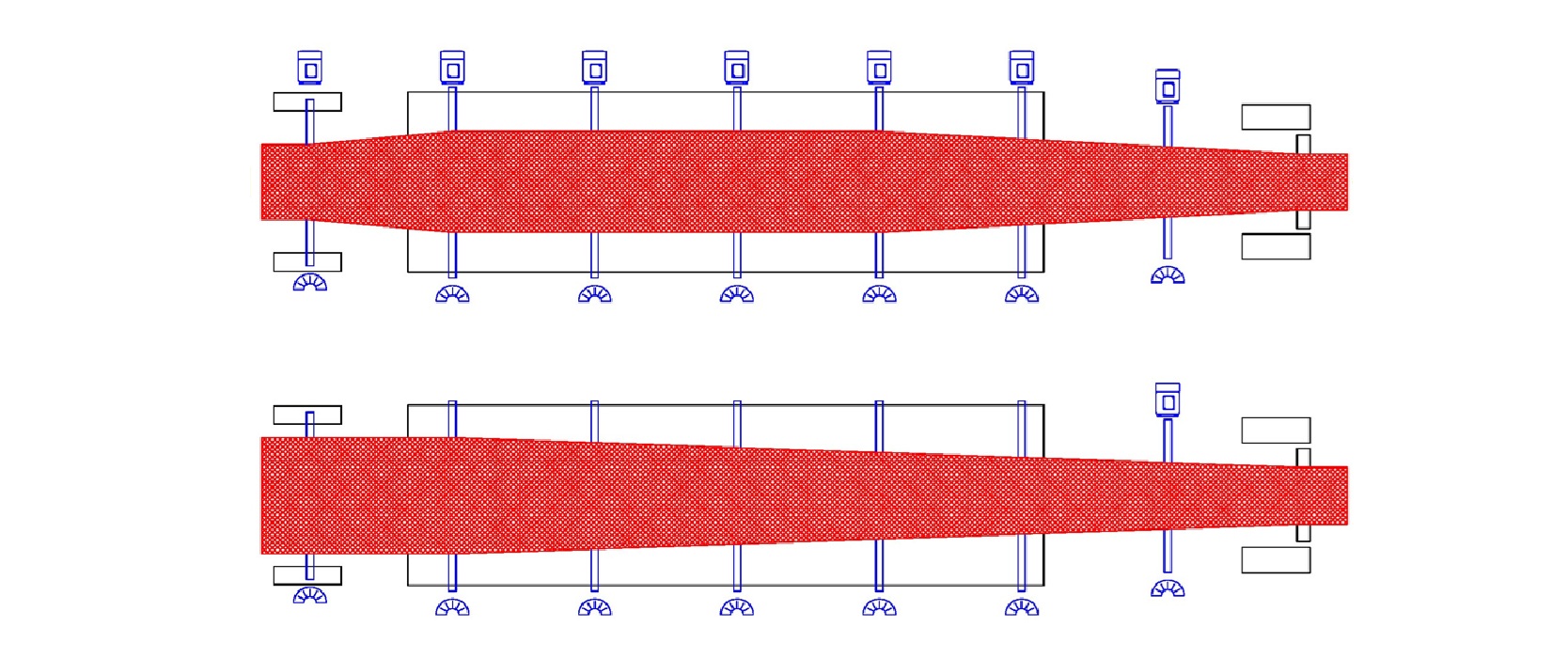

Stretching

Our stretching solutions offer exceptional biaxial stretching capabilities with precise control over angle and tension. This technology is highly versatile and suitable for textiles, geotextiles, and film materials that require large angle stretching to enhance mechanical properties and structural stability, meeting demanding functional and performance requirements.